Electronics Work Culture and Discipline

Systematic and Meticulous work has its own Rewards. An Engineers Notebook or a Hobby Experiments Log Book can go a long way in making a Cauliflower out of every Cabbage. (The credits of the Vegetable Analogy goes to Mark Twain)

1. Keep Work Place Clean.

Clean Tables and shelves every day before closing office, Put Cut leads and Solder shots in a separate cup to be accumulated and disposed later as these are toxic. In this cup other irritants like staple pins can be added and these can be clubbed in a month and disposed off as one metallic bulk for recycling. Never bring coffee or food to work area, Keep a waste paper basket on your side.

2. Work carefully to avoid injury

When cutting leads hold the lead in the hand and cut or it will fly all over the place. A piece like that may land on another equipment and cause shorts or it may go right into your eyes and cause blindness. Lead and Iso propyl alcohol and other Chemicals may be dangerous for health if handled carelessly. Do not use fingers, and teeth as tools it is bound to cause a injury to repent a lifetime. Be extra careful with 230V AC and more so with 440V 1 tr 2mA thru your heart and a weak streak of luck may be the last experience you ever had. Do not press your Luck too hard.

3. Protect Desk or table surface.

If you are cutting something let it not leave marks on table, even adhesive stains should not deface table, use a asbestos, Bakelite, fiberglass, hardboard surface which can be disposed once in a way. Before working put two layers of news paper on the table this prevents table from getting spoilt while soldering and newspapers being hygroscopic (water absorbent) they provide a natural antistatic surface to protect CMOS Ics and are nonconductors for any Live PCB kept on the paper.

4. Use tools and equipment’s in a gentle manner.

When you use weller Iron use it as a heat transfer tool never use it for prying or crimping leads or just pressing use pliers or other tools for that.

5. Document what you do and vice versa.

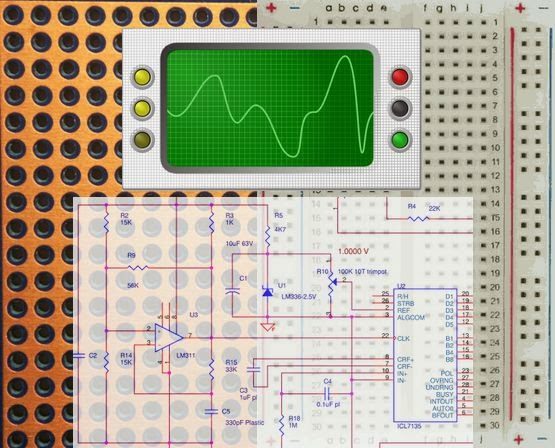

Have a register in which you can make records of what you did to solve a problem or what you learnt while making an equipment this information is valuable for the company to develop production methods and also useful to your team to solve a similar problem. Share abilities and skills with fellow employees but don’t share your company’s technology and database with any other company. When you leave a company use only the abilities and skills in that broad area to evolve as a professional.

delabs notes – 80s and 90s